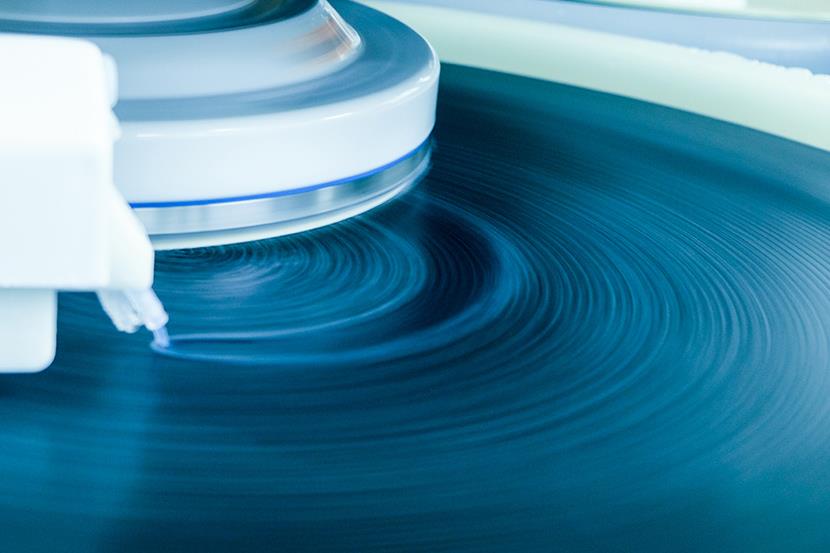

Protecting Wafers During Chemical Mechanical Planarization

Chemical mechanical planarization (CMP) flattens wafer surfaces prior to vapor deposition and subsequent processing steps using slurries comprised of fine abrasive particles, chemicals, and water.

CMP tool components made with Teflon™ resins keep process fluids and slurries that directly contact wafers uncontaminated. For example, the unmatched surface smoothness of Teflon™ PFA HP Plus resins inhibit buildup of slurry particles in system tubing.

Tubing

Tubing made from high-purity Teflon™ resins prevent the contamination of process slurries and ultra-pure water (UPW). The extreme chemical resistance of Teflon™ fluoropolymer resins make them compatible with even the most chemically aggressive deionized (DI) water used in dilution and washing.

Fluid Handling Components

Valves and fittings made from high-purity Teflon™ perfluoroalkoxy (PFA) and polytetrafluoroethylene (PTFE) resins ensure the highest performance of critical connections in CMP processes. Components like pumps, pressure regulators, and flow meters made from Teflon™ resins provide necessary protection against contamination and impurities.

Sensors and Flow Meters

CMP processes use capacitive sensors protected by high-purity Teflon™ PFA resins to monitor fluid levels for the harshest and most reactive chemicals. Teflon™ fluoropolymers insulate electrical components and cabling, providing additional protection against corrosion and contamination.

-

Cleaning and Etching

Teflon™ fluoropolymers improve efficacy of wet processing tools that clean and etch wafers. Learn more.

-

High-Purity Bulk Chemical Systems

Many bulk chemical distribution components use Teflon™ fluoropolymers to protect fluid purity. Learn more.