Embedded in the Past. Enabling the Future.

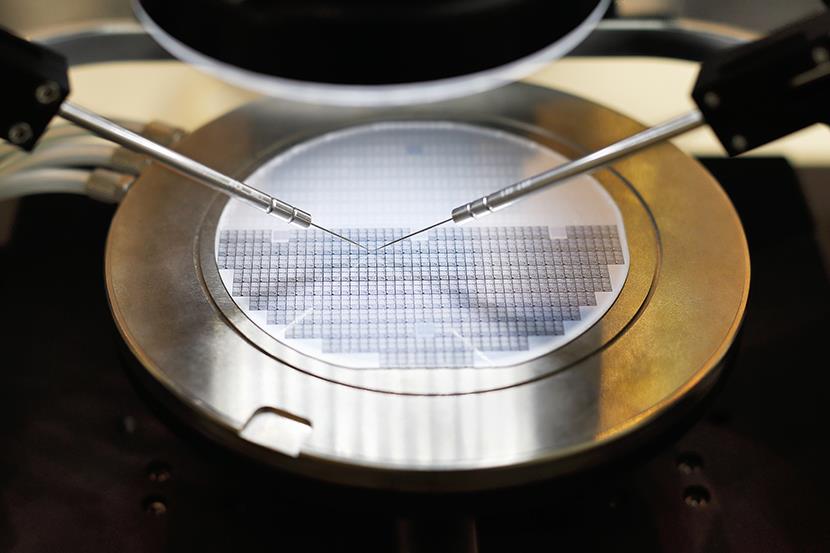

Teflon™ PFA, a perfluoroalkoxy copolymer resin, is available in pellet and powder forms. These fluoropolymer resins improve products manufactured for a wide range of industries, including the chemical processing, electronics, semiconductor, pharmaceutical, and biotechnology sectors.

Features and Benefits of Teflon™ PFA Resins

Teflon™ PFA resins can be processed via conventional melt-extrusion techniques or injection-, compression-, rotational-, transfer- or blow-molding processes. The high-melt strength and heat stability of Teflon™ PFA resins facilitate the use of relatively large die openings and high-temperature draw-down techniques—which also contribute to improved processing rates.

These resins combine the processing ease of conventional thermoplastic resins with the excellent properties of Teflon™ PTFE (polytetrafluoroethylene), which include:

- High chemical resistance

- Superior electrical properties

- High continuous service temperatures up to 260 °C (500 °F)

- Superior creep resistance at high temperatures

- Excellent low-temperature toughness

- Exceptional flame resistance

Teflon™ PFA Product Family

The Teflon™ PFA product family is comprised of resin grades with a range of melt flow rates (MFR), which are designed for various thermoplastic molding techniques—including tube and film extrusion—and injection-, transfer-, compression-, and blow-molding. This PFA product type is also available as a coating, film, or dispersion.

Additional key characteristics, features, and typical applications of these grades are listed in the table below.