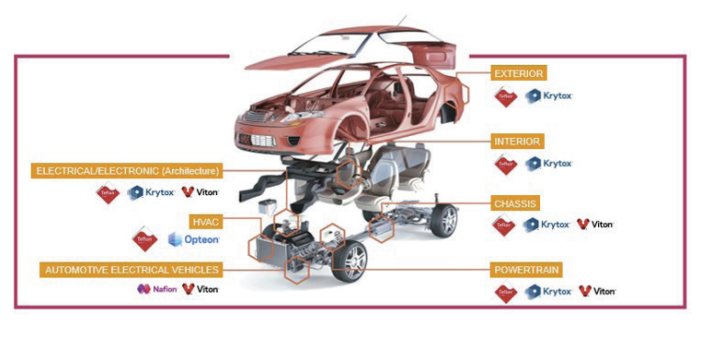

A Broad Range of Fluoropolymers Keeps Cars Running Smoothly and Efficiently

Automotive manufacturers create more value for car suppliers and buyers by building car components that better withstand high temperatures and corrosion. Teflon™ product solutions protect vehicles inside and out, paving the way for a better experience behind the wheel. High-performance fluoropolymers provide low-friction surfaces, increase efficiency and longevity, and enable car parts to withstand harsh environments.

The automotive industry uses Teflon™ fluoropolymers in:

- EV, including battery electrode binders, battery cell gaskets, coatings for battery active material equipment, e-motor shaft seals, sensor cables, busbar insulation, and NVH dry lubrication

- Fuel systems, including fuel lines, interconnect hoses, anti-expulsion tank valves, onboard diagnostics (OBD) sensors, and seals

- Powertrains, including internal shift seal rings, head gaskets, O₂ sensor hermetic seals, A/C piston rings, and valve stem seals

- Electric systems, including wire for O₂ sensors , throttle body injection (TBI) , heated seats, brake sensors, transmissions convoluted wire harnesses, anti-lock braking system (ABS) wires, control unit and sensor venting, exterior lighting venting, radar and proximity sensors used for blind spot detection, and automatic braking

- Brake systems that feature ABS interconnect hoses, impulse hoses at wheel, brake pad wear indicators, coatings for brake shims, and clips

- Interior/body, including power window vents, door hinge bushing sleeves, clutch and brake pedal pivots, interior fabric protectors, and coated weather stripping

- Chassis, including shock absorber piston seals, stabilizer bar bushings, steering ball joint inserts, steering assist pump piston rings, and axle venting